Cork stoppers – with extra membrane?

Cork harvested from cork oak tree

In the last decade, each cork oak tree has been harvested only once. In the last decade the main cork manufacturers have taken seriously the issue of TCA (the chemical that causes mouldy, musty taint in wine). Consolidation has seen some players hit the wall, while the big boys have put big money into technology to monitor and clean up the raw material.

Proprietary cleaning technologies, mostly based on deep steam-cleansing of cork particles, discs and whole single piece stoppers are combined with multiple quality assurance checks in the manufacturing process to eliminate batches of contaminated product before they reach the finished product stage.

Also in the last decade other businesses have been enticed alongside the cork industry, providing new barrier technologies to modify cork performance. After all, cork remains the most natural and sustainable stopper, and it has high consumer approval.

Such so-called barrier technologies that are now being added to the business end of corks have long existed in the food industry, and wine is, after all, legally a food. The two main protagonists in the barrier technology game are Procork and Nanocork. Both tout consistent oxygen permeability as their main function, and both claim TCA reduction as a side benefit of the technology.

Procork was first out of the blocks, and are now selling around 100 million units a year after their commercial introduction in 2002. The five-layer barrier acts as a TCA barrier, a flavour barrier and an oxygen barrier. Former CSIRO (Australia’s Commonwealth Scientific and Industrial Research Organisation) packaging, polymer and food sciences scientist, and founder of Procork, Dr Gregor Christie said “wineries using it stick with it because wines are better, stay fresh, keep character, don’t lose the edge which you get with oxidation, and don’t get a taint issue.“

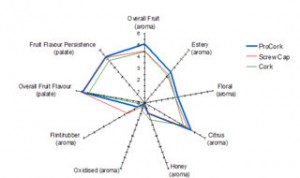

He said “two separate, independent AWRI (Australian Wine Research Institute) trials have shown that coated corks outperform screwcap and natural cork” adding “we have a number of Bordeaux chateaux starting with Procork technology after 3 years of carefully evaluated trials.”

Source: AWRI Commercial Closure Trial 2002, 24 Months, Procork

Christie explained “we started the work with an oxygen permeability control layer. The TCA adsorber layer is a side benefit we came across. It’s not a barrier, it doesn’t block it, but TCA will soak into it. Two of the other layers are barrier layers, so TCA can’t get through those layers.” Christie said the crystalline polymers of the barrier layers also stop glue taint. He added “The layer in contact with the wine also needs to be crystalline to stop wine flavour being scalped into the skin.”

The quality of the cork remains important with similar choices as for non-membrane cork, according to wine style. Christie said “the cork has to seal the bottle. We decided to purchase corks so we can control that aspect of it. We use top quality cork for top quality wines. With quicker turnover we can adjust quality of cork.”

The products in the Procork portfolio all have same barrier technology. Christie said “Platinum signature is our leading brand designed for reserve wines being cellared. This is top quality natural cork. Procork blue is right at the other end, using an agglomerate-technical cork. Technically they perform very similarly.”

Whilst the membrane is produced in Australia, all the production and distribution is done from Portugal. Corks are bought from big and small suppliers, all incoming lots meeting industry norms for quality control of the usual parameters such as TCA, sensory, density, mechanical performance. The final product said Christie “is slightly less permeable than a good quality cork, and more permeable than a screwcap with SaranTin.”

These are the same parameters for Nanocork, also produced in Portugal, under exclusive licence by the second largest cork manufacturer Alvaro Coelho, using the Bacchus barrier membrane. In their 24-month trial of Nanocork, AWRI reported that, in comparison to a reference 2 natural cork, a Supremecorq X2 (top of the range), and a Stelvin SaranTin screwcap, the Nanocork was fresher and fruitier than the driven alternatives, and less reductive than the screwcap.

The Bacchus membrane, in development for cork since 2002, uses a polymer that has been used in the bag-in-box industry for many years, and more recently in flexi-tankers for bulk transport. Managing director of membrane producer Bacchus Wine Closures, David Taylor said “we use a separate adhesive which is excellent for bonding plastic to wood in wet conditions. It gets harder and stronger in contact with moisture.”

Having trialled the membrane since 2005, Alvaro Coelho adds the membrane to colmated corks. They signed up their first paying customers this year and are confident of market demand. Henrique Figueridos, the sales director at Alvaro Coelho, said “this year we are expecting to sell more than 10 million. As orders grow we still can’t determine the final figure but it will be an excellent figure for a startup cork product. We expect to reach hundreds of millions in the coming years and our goal is one billion in a five year period.”

Figueridos asserted that the on-cost for customers is ‘tiny’. And Christie was equally bullish, saying “nobody’s not buying the product because of the price. We can match the prices that other people are selling at. “

The development lead times for such new technologies are not far short of the length of time the cork industry has been cleaning up its product, and the barrier guys are still early on the curve of potential take up, so time will tell if they become mainstream options for producers, but at least more options exist.